Materials and technology used on backpacks

ACD Membrane - Clothing - Tents - Sleeping bags - Backpacks - Gelanots

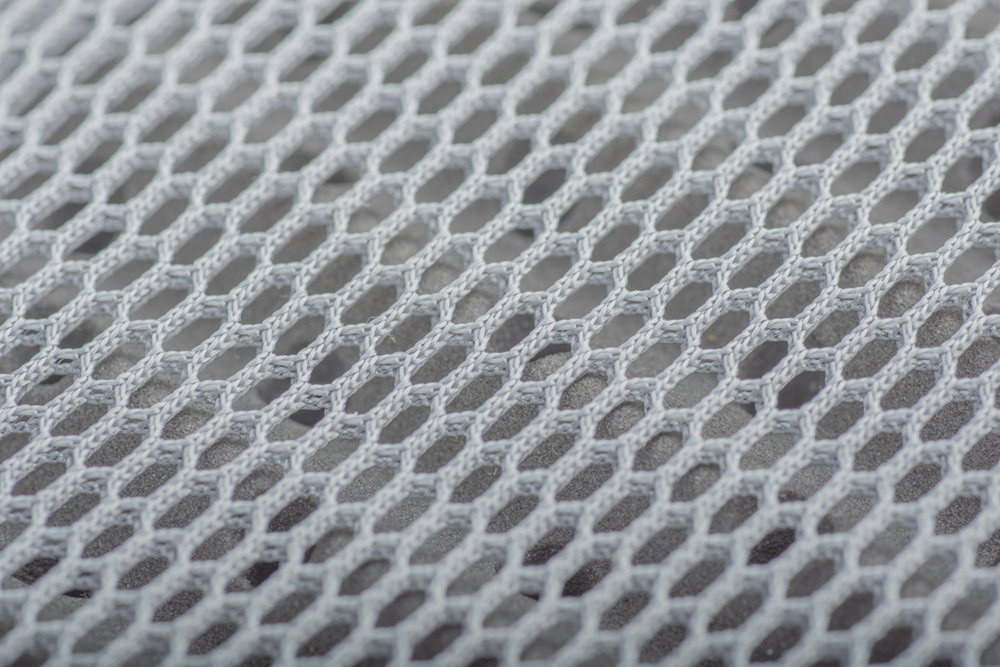

3D Mesh

Spatially woven material with high breathability allows almost resistance-free air flow through the bearing surfaces of the backpack carrying system, which significantly improves ventilation of the user's back.

3D Mesh back system

Comfortable, sewn back system consisting of non-absorbent pads covered with 3D mesh breathable fabric ensures effective ventilation of the back while maintaining optimal load distribution.

The back system is reinforced with a removable HDPE plate with integrated duralumin reinforcement, which helps to distribute the weight of the transported cargo on the back and eliminates the pressure of the transported objects in the back.

ABS

Or Adjustable Back System is the back system used in the largest backpacks in our range (55L or more). This system allows to adjust the length of the back in the range of about 10cm.

The system consists of a strap ladder on the back of the backpack to which a movable part with shoulder straps is attached by means of Velcro straps. Depending on which segment of the ladder is used to attach, the resulting back length is determined.

AVBS

Very comfortable, ventilated back system made of solid mesh, allowing maximum back ventilation while maintaining optimal load distribution. The pre-tensioning of the mesh is ensured by the peripheral wire frame.

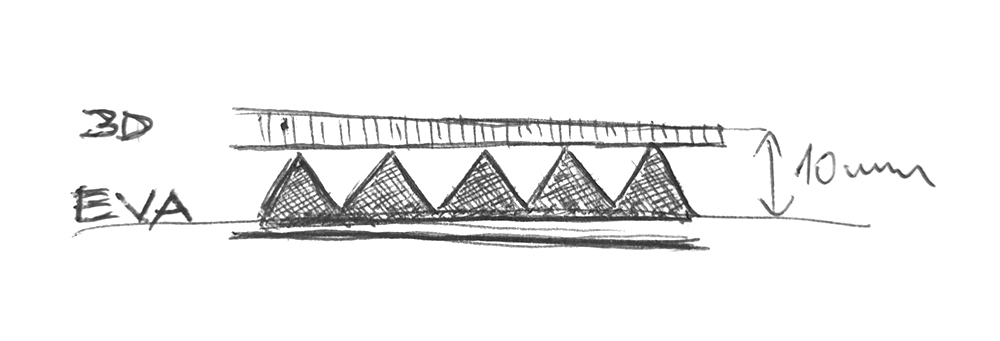

The 3D mesh combined with profiled and perforated EVA foam system maintains the center of gravity of the backpack as close to the back as possible, making it easier to move the backpack while walking, running or cycling and ensuring maximum back ventilation while maintaining optimum load distribution.

HDPE

High density polyethylene. It is temperature resistant in the range of -50°C to 110°C, is chemically resistant, odorless and also suitable for direct contact with foodstuffs, is non-toxic and, last but not least, it is recyclable.

HDPE is widely used, for example, in the production of water pipes, gas pipelines, chemically resistant pipes, automotive fuel tanks, insulating boards or welded products. It is increasingly used to produce wood substitute materials

Polyester fiber fabric with high strength, abrasion resistance and durability. Polyurethane coating on the inside of the fabric guarantees waterproofness of the material in the area.

Hypalon

Hypalon is a trademark for synthetic rubber known for its resistance to temperature extremes, ultraviolet light and chemicals. Hypalon has been developed for extreme applications such as white water rafts, protective suits and other outdoor equipment. It is also used on the surface of modern snowshoes and replaces neoprene as a lighter and stronger alternative.

It was developed by DuPont Performance Elastomers, a subsidiary of DuPont.

Nexus (Sweden) a Duraflex (Italy)

Branded plastic buckles with lifetime warranty of major world producers (Nexus - Sweden, Duraflex - Italy). Guarantee of quality and reliable operation.

Nifco is a worldwide supplier of functional plastic components for an extensive network of automotive product manufacturers.

Founded in Tokyo in 1967, Nifco has expanded to 17 countries with more than 35 manufacturing facilities and 4 R&D centers.

Nifco buckles are one of Nifco's eight major commodity groups.

Although Nifco is known for producing plastic components for the automotive industry, its extensive range of plastic clips developed primarily for use on luggage and apparel products is a very strong category of its production.

Every year, Nifco manufactures millions of buckles, which are divided into 33 categories, ranging from strap length adjusters, release buckles to shoe lacing systems. It is likely that if you come into contact with a plastic clip, it is quite likely that it could have been manufactured by Nifco.

The basic raw material for the manufacture of Nifco staples is Polyoxymethylene (POM). It is also known as polyacetal or acetal. It is a thermoplastic polymer used to produce precision parts. It is characterized by high stiffness, high wear resistance, heat resistance, elasticity, is tasteless and odorless, has a very low coefficient of friction. It is dimensionally stable even in damp, easy to machine.

Nylon 6,6

Nylon 6.6 (Polyamide 6.6) is used wherever very high mechanical strength, flexibility, stiffness, good heat stability and chemical resistance are required.

It is used in fibers for durable technical textiles, heavy duty carpets and molded parts (gears).

In the case of textiles, fibers are sold under different brands, such as Nilit or Cordura for luggage, but are also used in the automotive industry (airbag), workwear or for carpet fibers under the Ultron brand.

Very durable fiber developed in 1930 in DuPont laboratories in the USA.

Nylon 6

Nylon 6 fibers are stiff, have high tensile strength as well as elasticity and gloss. They are resistant to abrasion and certain chemicals such as acids and alkalis.

Nylon 6 is used in a wide range of products that require high strength materials. It is widely used for gears and bearings in the automotive industry. Used as floss in toothbrush bristles, surgical seams and strings for acoustic and classical musical instruments, including guitars and violins. It is also used in the production of large quantities of thread, rope, fiber, nets and cords for tires.

Nylon 6 has the potential to be reused as a technical raw material for the production of the new Nylon 6. It can therefore be recycled.

Nylon 6 (Polyamide 6) is a European variant of Nylon 6.6 developed to circumvent the US patent on Nylon 6.6.

Nylon Robic

The difference begins with the thread.

Nylon ROBIC® woven fabrics and materials are up to 50% stronger with up to 2.5x tear strength compared to standard Nylon 6 fabrics.

Nylon ROBIC® fibers are stiff, have high tensile strength as well as elasticity and gloss. They are resistant to abrasion and certain chemicals such as acids and alkalis.

They are also used in the production of a large number of threads, ropes, fibers, nets and cords for tires.

Simply, they are hard to break and very hard to tear.

New non-absorbent molded back system suitable for use in winter, without snow and water repellent.

Zips of a renowned Japanese manufacturer, which are among the best in the industry in the world.

Zippers of this brand guarantee quality, long life and reliability. Components of small size but of great importance, because their trouble-free functionality is usually a condition for the functionality and usability of the whole product.